Download Autopipe User Manual

22.07.2019

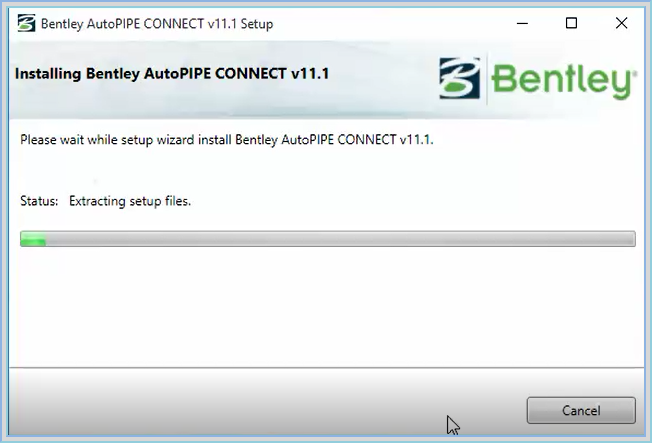

Note: Bentley IEG License Service is NOT required to run this AutoPIPE version. Bentley AutoPIPE V8i is a stand-alone, engineering application for the calculation of piping stresses, fatigue stresses, fluid transient, bowing or thermal transient analysis, flange or pipe support design, and.

Download Autopipe User Manual Pdf

Piping Stress Analysis

Piping Stress Analysis

Hello, first time poster with a query regarding piping stress analysis.

At the moment I work in plant design Process Engineer. Before issuing drawings we send selected lines out for Stress Analysis (our somewhat simplified criteria for Stress Analysis is D>2', dT>100 Deg C). It is now desired to do this analysis in-house.

I've taken it upon myself to research this.

I've assembled numerous guides (including the CASTI guidebook to ASME B31.3 & Process Piping the Complete Guide by Charles Becht).

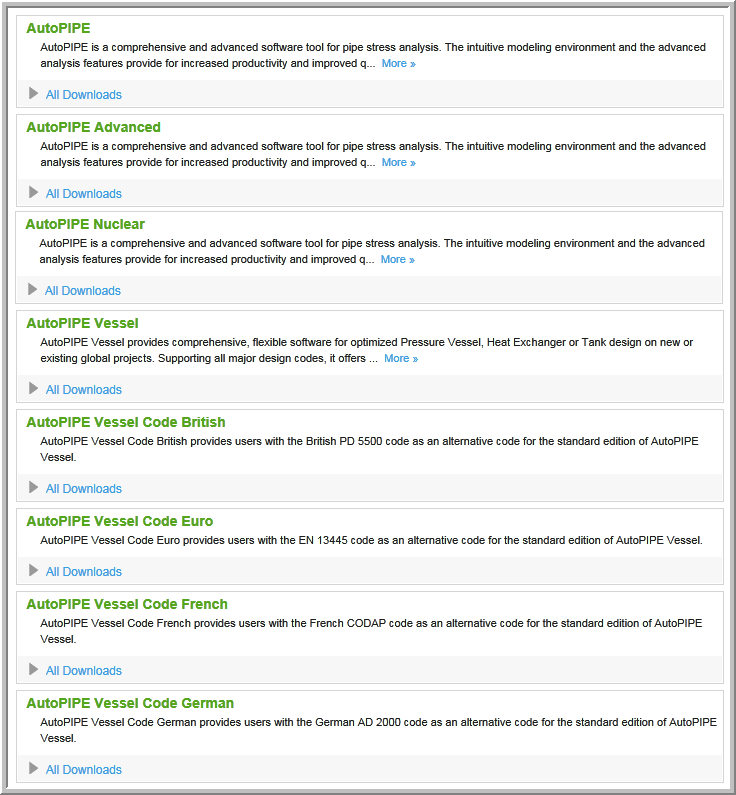

I know that Caesar, Autopipe and others are used, but for various reasons they don't want to go this route. Instead they want to establish either a guideline or program that will cover the stress analysis.

We can characterise out piping networks quite easily, in terms of fittings, equipments dimensions, operating conditions etc. via our database system and 3d model.

So what I'm really looking for is somebody that works at this day to day, to give some pointers. I've spoken to my former mechanical engineering lecturer who thinks developing it from the ground up is a bad idea (i.e. go the Caesar route). I would like to get some other opinions on this. If it really is a bad idea, its best to find out at this early stage.

From reading the guides, a lot of it seems pretty vague, or at least up to the designers dicretion.

I would like to know how those working at it proceed and if to develop our own properitary procedures/software is feasible.

I'm assuming for all this that ASME B31.3 is the main guideline to consider regarding Stress Analysis for Process Piping.

Thanks for getting this far!

At the moment I work in plant design Process Engineer. Before issuing drawings we send selected lines out for Stress Analysis (our somewhat simplified criteria for Stress Analysis is D>2', dT>100 Deg C). It is now desired to do this analysis in-house.

I've taken it upon myself to research this.

I've assembled numerous guides (including the CASTI guidebook to ASME B31.3 & Process Piping the Complete Guide by Charles Becht).

I know that Caesar, Autopipe and others are used, but for various reasons they don't want to go this route. Instead they want to establish either a guideline or program that will cover the stress analysis.

We can characterise out piping networks quite easily, in terms of fittings, equipments dimensions, operating conditions etc. via our database system and 3d model.

So what I'm really looking for is somebody that works at this day to day, to give some pointers. I've spoken to my former mechanical engineering lecturer who thinks developing it from the ground up is a bad idea (i.e. go the Caesar route). I would like to get some other opinions on this. If it really is a bad idea, its best to find out at this early stage.

From reading the guides, a lot of it seems pretty vague, or at least up to the designers dicretion.

I would like to know how those working at it proceed and if to develop our own properitary procedures/software is feasible.

I'm assuming for all this that ASME B31.3 is the main guideline to consider regarding Stress Analysis for Process Piping.

Thanks for getting this far!

Comments are closed.